Based in Holland and founded in 1990, Alkondor engineers and produces façades, windows and doors, particularly for large and complex projects. The team work on a host of construction projects from residential to non-residential buildings, like hotels and cinemas, and have specialist expertise with complex architecture programmes.

Digitalising to reduce risk

With their own production facility in the Netherlands, 150 employees support Alkondor’s activity including Chris Schoneveld, BIM Manager and Bram Kotter, CEO. When Chris joined the team five years ago, his remit was to focus on all of Alkondor’s digital processes, including how the team can use digital solutions for better insights and modernise their ways of working.

At the time, the team used many time-consuming processes which included printing physical copies of PDF documents and delivering them between departments and to the factory manually. This meant that there was a layer of risk added to projects – working in such manual ways mean newer versions of drawings were again hand-delivered to production teams in the factory. “It was very easy for things to go wrong,” reflects Chris. “We were working in a way that was open for errors and meant there was a lot of work for everyone; we used Excel forms, handwritten notes, PDFs and spent a lot of time transferring and tracking documents.”

With all documents stored on local servers, soon the team recognised they began to have issues with different naming conventions on drawings and poor practices led to miscommunication and confusion. “It would be difficult to search between different documents,” says Chris. Alkondor decided that they needed to change the way they in which they managed their documents and knew that investment in their digital processes would help them be more efficient and collaborative when it came to working on their projects.

step change in ways of working

“We were already using some digital products such as Revit,” reflects Bram. “We were working with ITANNEX (Arkance systems), an Autodesk reseller, who introduced us to Autodesk Construction Cloud’s BIM 360 platform.” Alkondor began trialling BIM 360 to see how the functionality could support the team with their document management activities as well as supporting version controlling and issues management.

To start with, Alkondor undertook a pilot project with a small group who trialled using BIM 360. The pilot group tested how the team could share documents and data from Autodesk’s Revit platform straight into BIM 360, but they also tested other functionality like quality control and issues management.

After an initial trial, Alkondor decided that they wanted to roll out BIM 360 across all of the organisation and provide dedicated training to their team to ensure this investment was firmly embedded in the company’s ways of working. Bram introduced the solution during learning sessions for all employees, with Chris taking colleagues through the features and functionality. Chris also ensured he was available on site so the team using the solution were able to ask questions and troubleshoot collaboratively.

“I think the best features we have found in BIM 360 is the quality elements we can derive. We can document and freeze elements at certain points during construction,” says Chris. “This means we can complete extra quality checks which avoid extra costs that could be incurred to our products we install on site.”

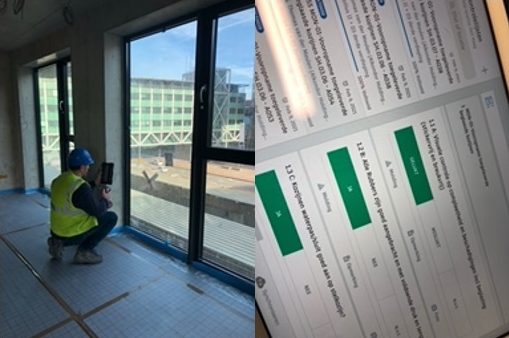

The team use Ipads on construction sites and in the factory where they can access BIM 360. They use digital checklists for quality checks, and this also means they reduce the amount of paper used, ensuring Alkondor’s carbon footprint remains as low as possible.

Having digital document management practices means that all Alkondor team members can find documents quickly and easily using Autodesk Construction Cloud’s BIM 360 platform. “Being able to search and find documents easily saves a lot of time,” says Chris. “We can also see version history and there is a clear audit trail when it comes to changes.”

Capturing learnings for greater insights

When it comes to learnings on each project, Alkondor use BIM 360 to capture insights on the progress of their projects to provide greater certainty. Chris remarks: “We have integrated PowerBI with BIM 360 so we can visualise our data and improve outcomes. We use PowerBI and BIM 360 to provide detailed information about the project’s progress. Sometimes we adjust production and engineering processes where necessary to ensure there is no disruption to our projects.” For project managers at Alkondor, this provides them with an overview of each project helping them to make more informed decisions.

For Alkondor, quality is underpinned by their use of BIM 360. “All of our windows and doors are digital assets within the BIM 360 asset module,” says Bram. The team use this module to track the progress from their factory to project handover. “We add quality checks during the different stages of production and element mounting,” says Bram. “We can visualise our asset progress again using PowerBI dashboard updates with the help of Autodesk’s data connector. This updates every two hours and provides valuable information to our managers,” says Bram.

The team managers in the production area can review both data and issues using this functionality. This means that communication between the production and preparation departments are much more streamlined.

“Things are much quicker and time isn’t lost waiting on information,” – Chris Schoneveld, BIM Manager, Alkondor

“For example, colleagues in the production areas can attach issues to drawings to ensure the right materials are being ordered. This can all happen in BIM 360 with ease.”

This also means the teams have much more insight into what is going wrong and what can be done to change it. When it comes to Alkondor’s use of BIM 360, the company are embedding its use more and more. The team have used BIM 360 on 197 projects, documented 13810 issues and created 17500 checklists as well as 10500 assets.

Data, data and more data

For Alkondor, having meaningful data available to analyse is significant. Chris reflects: “We have data and dashboards to make it immediately visible. Previously, we couldn’t analyse anything, but now we can use BIM 360 to analyse everything.” When it comes to using this data, it is invaluable to be able to document and capture the quality of products at a moment in time. “In the past, we were unable to confirm with our clients that there weren’t any scratches on door panes, broken glass or concrete stripes. So if there was a defect afterwards, customers could blame us and ask to front the costs for solving it,” says Chris. Now, Alkondor has evidence of the quality of their outputs on a set date. Which is stored in BIM 360. Depending on the project, that could save somewhere between 10,000 euros to 100,000 euros.

In the future, the team is looking to add in sensor data, so that the business can offer services like predictive maintenance. As an example, they could use this functionality to identify that one door opens once a year, while another opens a thousand times a year. They could use that data to inform predictive maintenance schedules.

For Alkondor, embracing technology of the future like the use of robotics in their factories means they will enable their workforce to focus on higher value and complex work. Being able to offer data to their customers also means that they can be more transparent and provide information that will help their customer to better manage the asset in the future.

“We are committed to embracing technology today so that we can use it for the better in the future,” says Bram. “This also means we can be more flexible as a company – for example pivoting our market offering from projects to ongoing services which will provide us with more revenue streams to explore. And at the heart of all of this for Alkondor is using their data for the better.

The post Data-Driven Insights Improving Quality With Alkondor appeared first on Digital Builder.