There have been warning signs in the construction sector for years. The industry creates high levels of physical and digital waste, with 10-15% of materials wasted on every build

Construction and the built environment account for nearly 38% of all energy-related carbon emissions around the world. And what’s more, we’re battling low productivity and a growing skills shortage. From an environmental, social and economic perspective, it’s simply not sustainable.

But crucially, there’s greater appetite for change in construction than ever before. At two events, London Build and the Festival of Digital Construction, panellists came together to discuss the opportunities for change in the industry.

7 key takeaways on the future of sustainability in construction

1. Incremental change won’t cut it: we need a paradigm shift

The construction industry has been doing the same things for a long time. According to Dale Sinclair, Director of Innovation, EMEA at AECOM, you have to look to the beginning of the twentieth century for the last major innovations like steel and drywall. “If you think about the Empire State Building and the speed it was constructed, that would still be impressive today,” he noted.

Many of the recent improvements in the industry have focused on optimising traditional approaches – but with pressures like the climate crisis and population growth, we need more radical change. As Jaimie Johnson, Head of Global Systems at Bryden Wood put it, “We can’t use traditional techniques to meet population growth. We’ll kill the planet before we house the planet.”

The construction industry will have a huge impact on the future of the build environment, affecting the lives of people hundreds of years from now – as Emilia Hagberg, Senior Sustainability Manager at Skanska, explained. Whatever lens you use, it’s time for construction to do something fundamentally different.

2. There’s a carrot, as well as a stick, for improving sustainability

Companies are facing very real commercial pressures to become more sustainable. Investors want to know that companies are dealing with the risk of climate change, by adapting their business models. There’s greater public and government pressure, which may result in binding regulations.

And critically, owners are beginning to demand greater sustainability, from construction through to operations. Tom Blankendaal, Project Manager, Circular Economy at BAM, shared a story of working with a Dutch bank to create a more sustainable design. “We eventually redesigned the whole project with a trade-off matrix on different sustainability factors, such as energy usage, circularity and total cost of ownership. In the end, we made some very radical design decisions.”

There are also commercial benefits. As Dr Bonahis Oko, Sustainability, Carbon and Environmental Lead at Bouyges Energy Services explained, companies should recognise this “carrot” as well as the “stick.” “Sustainability measures often drive greater efficiency on projects: for example, reducing mistakes also reduces waste. It’s important to look ahead too. Think of sustainability as a factor in the future of the business: an R&D investment rather than just an obligation to fulfil.”

3. True sustainability accounts for the whole life of an asset, so adaptability matters

For a meaningful view of an asset’s sustainability, owners have to consider its whole life emissions – which can open up new ways of thinking. As Dale at AECOM explained, “The construction of a building only accounts for 20% of its whole life costs. If you make it 20% more operationally efficient over its lifetime, you effectively get the building for free.”

Adaptability is essential for maximising a building’s usefulness, prompting a move to long life, loose fit assets. “The most sustainable building is the one that already exists,” explained Az Jasat, Senior Industry Manager, Industrialised Construction, Autodesk.

Jaimie at Bryden Wood recommended we take inspiration from the Victorians, who built incredible overengineered brick buildings which have been converted to many uses over the years, from water stations to climbing walls to offices to flats. “Let’s be the modern Victorians and create the kind of infrastructure that’s superbly well-built for a 150-year lifecycle,” he said.

4. Industrialised construction and design for manufacture and assembly (DFMA) will be critical

By applying manufacturing techniques to the built environment, industrialised construction and DFMA can increase the efficiency and reduce the emissions of projects. According to Az at Autodesk, “these two movements are our best chance of turning this ship around.”

Going one step further, some organisations are exploring the potential of platforms in construction: using consistent components and processes to construct a wide range of buildings, in a similar approach to furniture designs at IKEA.

Jaimie at Bryden Wood explained how the Construction Innovation Hub examined the UK’s public sector construction pipeline across every department. The project found that 70% of the total pipeline could be constructed with the same structural kit of parts, the equivalent of £35bn of assets.

“More than half of the space in schools, hospitals and prisons isn’t sector specific; it might be hallways, toilets, storage or bedrooms,” he said. “If you use the same products and processes across these platforms, there’s much more scope to optimise the components to make them as sustainable as possible.” By using common components on a project called The Forge in London, Bryden Wood saved 20% of the embodied carbon on the build.

5. Both old and new materials have huge potential

Re-evaluating which materials are used in construction – and how – will be critical. As Frank Blande, Senior Sustainability Manager at Multiplex, highlighted, concrete and steel are the two biggest emitters in construction’s carbon footprint.

Innovations in materials science could help to solve this issue, as could the renaissance of older building options. Tom at BAM advocated the potential of engineered wood, as a means of not only reducing carbon emissions but capturing them. The largest timber tower in the world was recently completed in Norway, reaching 18 storeys.

There are many elements that impact the sustainability of materials, so better data will also help teams to make more informed decisions about pay offs. Tools like the Embodied Carbon Calculator are already supporting client dialogues. Tony Saracino, Senior Sustainability Success Manager at Autodesk, advocated harmonised ISO standards for material profiles, to take the industry away from rule of thumb estimations.

Better data also creates the opportunity for materials passports, so that components can be re-used; given that currently 54% of demolition materials go into landfill, this could have a substantial impact.

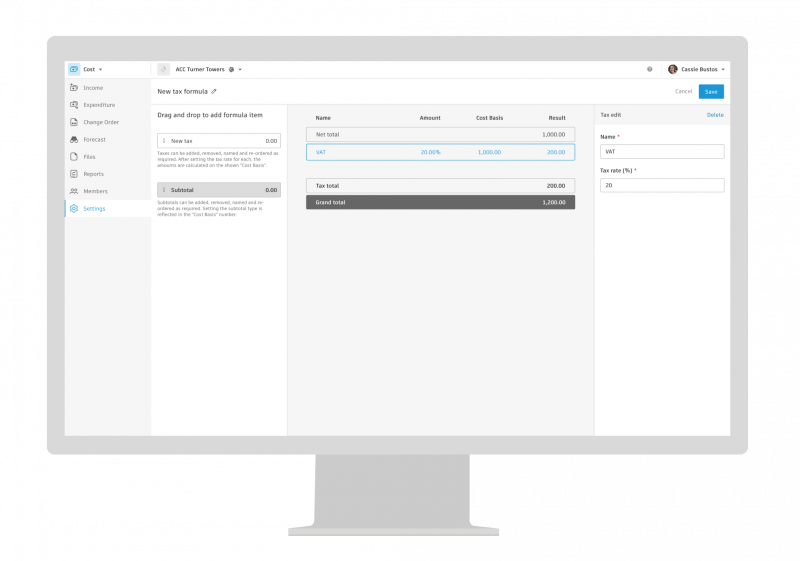

6. Data will be the force behind all of these changes

Creating a more sustainable industry must start with data. As Frank at Multiplex explained, “Clear and accurate data helps us to better understand where we actually are – our sustainability baseline. It’s then possible to put data-driven strategies in place. As a sustainability team, we’re working with other disciplines across the business to get accurate data in place and set minimum data requirements that cover the business, supply chain and collaborators.”

Making this information available to project decision makers will help to improve design management, planning and quality. Data can also support closer collaboration with clients. AECOM is currently working with Autodesk on a viewer that simplifies information into a really intuitive interface: allowing everyone to get to grips with the data and understand the implications of the design.

However, organisations can encounter challenges with data management: currently lots of sustainability managers’ time may be spent collating siloed information manually, so automating data capture and analysis will be hugely valuable. Going forward, creating feedback loops about the real-world operations of buildings – through tools like digital twins – will also be key.

7. All the stars are aligned: now it’s up to the industry

Sustainability presents significant opportunities for construction, but there are widespread cultural barriers to overcome. Construction is an incredibly risk-based industry, with many companies trying to protect thin profit margins. According to Frank at Multiplex, that can make innovation and new approaches unattractive – as organisations often can’t look to people that have tried it before.

But as Rachael Atkinson, Construction Solutions Executive at Autodesk, highlighted, “Children have been brought up to understand the importance of the environment. Future generations will enter the industry with this whole new mindset – so maybe it’s us that need to change.” This is a collective effort, and transparency – and learning from one another – will be critical. As Tom at BAM explained, “Rather than copyright, we see it as the right to copy.”

All of our panellists are clear on the need to change, right now. As Dale at AECOM said, “We’re dealing with a significant time gap. In five years’ time, the aspirations from owners and occupiers will be completely different. Owner need to shift their thinking into the future today.”

Jaimie at Bryden Wood concluded, “All of the stars are aligned: the climate crisis, the business imperative and government policy. Plus the financials: if you make a building that’s 20% more sustainable, the construction is essentially free. What else are you waiting for? Now is the time for every business to engage and accelerate the move to sustainability.”

Check out our recent report on the path to sustainability for construction business leaders.

You can view the panel discussions in full here:

London Build: Industry Sustainability and Productivity – Unlock the Benefits and Impact of Industrialized ConstructionThe Festival of Digital Construction: The importance of data and how it is impacting the construction industry

The post 7 Things to Know About the Sustainable Future of Construction appeared first on Digital Builder.