The phrase “digital twin” regularly comes up in forward-thinking conversations about construction innovation and technology, making it one of the most buzzed about topics in the industry.

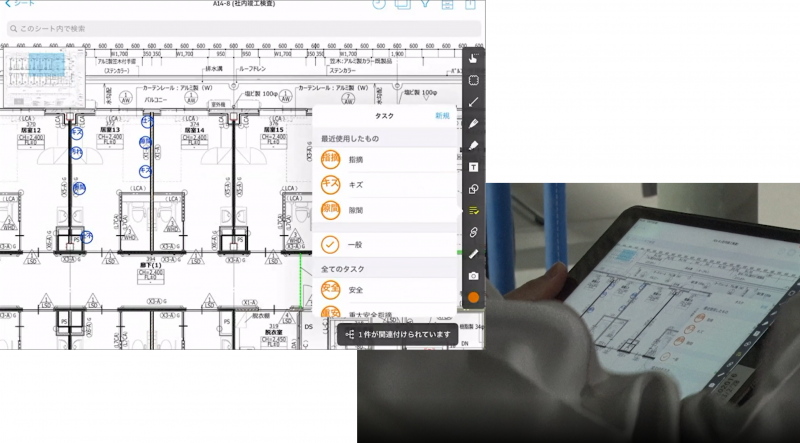

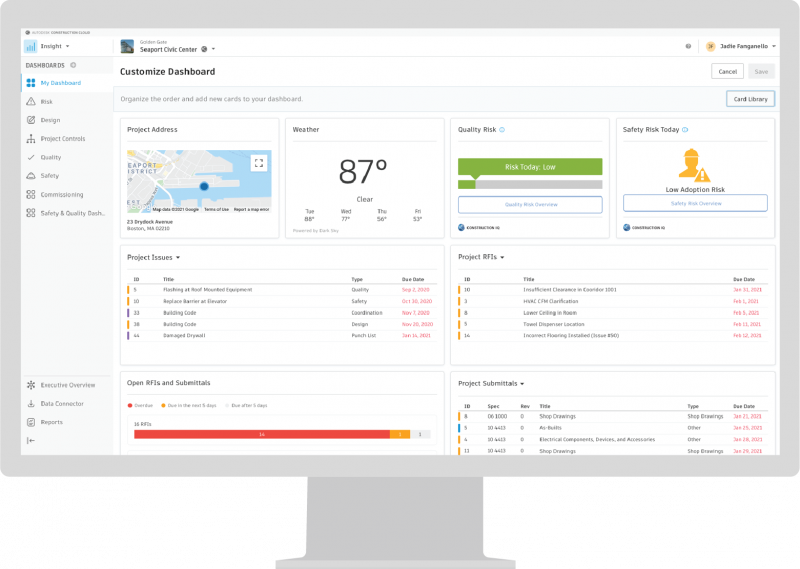

What exactly is a digital twin? Simply put, it’s a digital replica of a built asset. It’s important to note that a digital twin isn’t just a static copy of a building. Ultimately, it provides a bi-directional link between the digital and physical worlds, so that the digital reflects everything that’s happening with regard to a real world asset’s utilization performance.

More than just a buzzword or trend, digital twins can truly transform how we develop and maintain buildings.

On Episode 16 of Digital Builder, Bob Bray, Senior Director & General Manager for Autodesk Tandem and Tim Kelly, Senior Product Manager at Autodesk, joined us to shed light on the ins and outs of digital twins. In this episode, we covered:

What a digital twin is and how it’s createdThe benefits of adopting a digital twin Tips and avoidable challenges when implementing a digital twin Maintaining digital assets and the future of digital twin technology The incubator process at Autodesk

(function() { var qs, js, q, s, d = document, gi = d.getElementById, ce = d.createElement, gt = d.getElementsByTagName, id = ‘soun_der’, b = ‘https://embed.sounder.fm’; if (!gi.call(d, id)) { js = ce.call(d, ‘script’); js.id = id; js.src = b + ‘/embed.js’; q = gt.call(d, ‘script’)[0]; q.parentNode.insertBefore(js, q);}})();

powered by Sounder

“Don’t think about digital twins as something that’s so far-fetched that you can’t achieve it today. It’s a tool that you can start small with and ultimately develop over time.” — Tim Kelly

Interested in learning more about Autodesk Tandem? Check it out here

New Episodes Every Two Weeks

Digital Builder is hosted by me, Eric Thomas. Remember, new episodes of Digital Builder go live every two weeks. You can hear more episodes like this one by subscribing to Digital Builder on Apple PodcastsSpotifyStitcherGoogle Podcasts, or wherever you listen to podcasts.

You can also subscribe to our email list with the form below so you’re the first to hear when new episodes are released:

Getting Started with Digital Twins: 3 Steps to Get It Right

One of the key themes in this episode is simply deciding where to start the process. If a hypothetical owner or contractor wanted to implement a digital twin, what are the initial steps they should take?

According to Bob and Tim, construction professionals should do the following.

1. Understand the high-level benefits of a digital twin

Remember, a digital twin is more than just a replica of a built asset. Rather, it’s a dynamic, real-time version of a building that’s closely linked to the physical asset. Ideally, both the physical and digital assets are maintained properly in order to fully reap the benefits of having a digital twin.

As Bob puts it, “At the end of the day, a digital twin is — if it’s healthy — a living, breathing entity. It’s the current state of your facility and everything about it.”

It takes commitment to create and maintain a digital twin, so in order to obtain buy-in from stakeholders, you need to help them understand the advantages of having one.

An important benefit is that a digital twin collects real-time performance data. It displays this data in a meaningful way to provide insights that can help owners better understand how their assets are doing and if they are meeting the necessary KPIs.

“If you have certain sustainable goals, you’ll be able to see if you’re achieving them. If you have equipment and want to measure mean time between failure, having a digital twin helps you do that,” explains Bob.

The bottom line, he says, is that “A digital twin gives you the knowledge to inform, predict, and look at future decisions based on how that asset is performing in the real world.”

Another important value proposition is the time and cost savings that owners can realize through the use of digital twins.

Rather than doing expensive site surveys, says Bob, owners can rely on digital twins to give them the data they need without having to physically be in the building.

A digital twin can also streamline building maintenance, as it keeps all the necessary information under a single pane of glass. In many traditional buildings, data is fed into disjointed systems that make it difficult to surface meaningful insights. A digital twin, in contrast, provides a holistic platform on which data can be accessed and used.

2. Start small and develop your digital twin process over time

Once you get the green light to get started with digital twins, it can be tempting to try to do as much as you can right from the get-go.

However, your efforts will be much more successful if you start pragmatically. The key isn’t to revamp all your assets and collect tremendous amounts of data. It’s far better to be intentional with what you build and collect. Prioritize the assets that you absolutely need to manage first and go from there.

“One of the challenges that people face is they want to collect absolutely everything about everything,” says Tim. “But if you’re intentional about what you want collected and what data you want to leverage — and you can think about how that gets organized — then you’re in a much better spot.”

If you aren’t sure where to start, Tim recommends looking at industry standards and using them as guidance. “Ultimately, you can whittle that down and narrow that information over time and put it into practical application.”

It’s also important to have a discussion with your team on what assets are required, says Bob.

“An essential action step is getting together with your facility management team and understanding — from an FM perspective — the assets you need to manage in that facility going forward,” he says.

Bob recommends asking questions like:

What are the spaces in that facility that I need to utilize and manage effectively?How do the systems that connect those assets actually work?What data do I need for each of these pieces?

Once you have that conversation, get the necessary components in the contract and have the team deliver everything in a digital format, rather than an analog set of papers.

“If we can get this data in our hands at project turnover, then I think that’s where the industry changes and the opportunity that owners have to really kick start this process and put it into high gear,” Bob adds.

3. Assign a point person to maintain digital twins

The success of your digital twin doesn’t just lie in its creation; you need to maintain it as well.

As Tim points out, “If you’re not using the information [from the digital twin], and you’re not engaging with it, then you’re ultimately going to have stagnant data.”

He adds, “You need to be actively engaging and using the digital twin to maintain and operate the facility.”

Maintaining your built and digital assets takes commitment and ongoing effort. Buildings and facilities change over time. Components are swapped out, renovations take place, and assets need to be updated to stay current.

Amidst all this, it’ll be extremely helpful to assign a point person to look after the digital twin and ensure that it evolves along with its physical counterpart.

“Certainly, if you’re looking at adapting a digital twin, you need a point person or a team member involved,” remarks Tim.

“It could ultimately be part of the capital projects team or maybe even part of the facilities maintenance team, but I would say you need to appoint someone to look after that and be the liaison for other contributors and consumers over time.”

Depending on the situation, it may also make sense for contractors to take on the responsibility.

“There’s a clear opportunity for AEC firms and for contractors to become a better partner and help manage that digital data on behalf of that owner,” says Bob.

“Many times, owners don’t have the detailed experience in this, and contractors do. That’s one value that they can bring to the owner. It tightens up the partnership between the contractor and it facilitates better communication between the two. It’s also a much longer opportunity to work together and delivers more value to the owner over time.”

Listen to the Full Episode of Digital Builder

During our conversation Bob and Tim shared so much more about digital twins and how AEC pros and owners can be more successful when using them. Catch the full conversation by checking out Episode 16 of Digital Builder on the following platforms:

Apple PodcastsSpotifyStitcherGoogle PodcastsOr wherever you listen to podcasts

The post Digital Builder Ep 16: 3 Things We Learned About Getting Started With Digital Twins appeared first on Digital Builder.

Did you miss our previous article…

https://www.dennis-construction.com/?p=947

![Year over year growth, BuildingConnected data reveals top 15 cities with most new projects published [report]](https://www.dennis-construction.com/wp-content/uploads/2021/10/Year-over-Year-Growth-800x392-1.jpg)

![Top 15 cities, BuildingConnected data reveals top 15 cities with most new projects published [report]](https://www.dennis-construction.com/wp-content/uploads/2021/10/Top-15-cities-800x382-1.jpg)