The name behind countless successful electrical and mechanical infrastructure designs of building projects in Turkey and across the globe, Anel Group stands out with its expertise in BIM (Building Information Modeling). The organisation uses Autodesk Architecture, Engineering & Construction (AEC) collection including the Autodesk’s Construction Cloud platform. These include an integrated BIM toolkit, BIM 360 Field and Autodesk BIM Collaborate Pro cloud services, with the aim to support Anel achieving their global goals that require high efficiency, remote collaboration and coordination capabilities.

Passion for implementing complex projects with an environmental approach

Anel Group’s journey began with the establishment of Anel Elektrik in 1986 by Electrical Engineer Rıdvan Çelikel. Established 35 years ago, the company is transforming into a 2,000 people strong group of companies that operates in the fields of panel production, electrical and electronic systems of ships, renewable energy, recycling and operational maintenance, as well as electrical and mechanical contracting.

Since its inception, the company has successfully delivered more than 200 projects spanning a total area of over 13 million square meters in 14 countries across three continents. In addition to its ongoing MEP operations in Qatar, the United Arab Emirates (Abu Dhabi and Dubai), the UK, the Netherlands, Turkey and Azerbaijan, the company is also engaged in operational maintenance services, low voltage panel production, electric and electronic systems of ships (defence industry) and recycling.

Anel Group Tender and Procurement Director K. Serkan Kılıç, who is also an Electrical Engineer, said, “We are a team striving to deliver solutions for the world we dream of” and added: “A single structure has the power to make a big difference in the world: A bridge connecting two continents, an airport that makes the world feel a lot smaller than it is, a hospital that saves lives… We can list a myriad of examples from world history.”

Emphasising that the success of a building project depends on the ability of combining engineering skills from different disciplines in harmony, Kılıç said, “We leverage our engineering skills in designing the electrical and mechanical aspects of a building. We are passionate about realizing large-scale and complex projects in different regions of the world. With a view to contributing to an environmentally, socially and economically sustainable world, we combine our engineering and technology capabilities with our strategic skills and take innovative initiatives.”

“We leverage our engineering power to create solutions and aim to use cutting-edge technologies that we could benefit from the most. Especially in a two-year retrospect, Autodesk AEC Collection and Autodesk Construction Cloud’s solutions have helped us immensely as we seized opportunities around the globe.” —Serkan Kılıç, Tender and Purchasing Director, Anel Group

Engineering strength powered by technology

Autodesk’s AEC Collection as well as their Construction Cloud forms the technology backbone that supports Anel Group’s engineering strength and strategic capabilities. This solution package, which includes an integrated BIM toolkit and is designed for the building industry, has also played a pivotal role in Anel Group’s international expansion efforts since 2016.

Anel Group BIM Manager and Mechanical Engineer Ümit Balaban has led the establishment of the BIM infrastructure and the introduction of BIM processes across Anel Group. He said, “The BIM processes need continuous improving to keep up with the ever-evolving technologies and engineering industry.” He is responsible for managing the compliance of the projects undertaken by the company with the BIM processes and provides support to all BIM managers assigned to the projects. He is also the founder of the BIMgenius Community, a not-for-profit made up of professionals who have come together to collaborate to support the digitalization of the architecture, engineering and construction industries.

The Anel Group team can manage electrical and mechanical projects via the AEC Collection in alignment with BIM processes, starting from the tender phase, all the way to the design implementation and delivery phases via the Autodesk Construction Cloud. Anel Group, which started using BIM 360 Field, BIM 360 Docs and made it its primary application following the increasing need for working remotely due to the pandemic, leverages the advantages of savings and efficiency of cloud services in field monitoring and management, documentation management, remote collaboration and coordination activities.

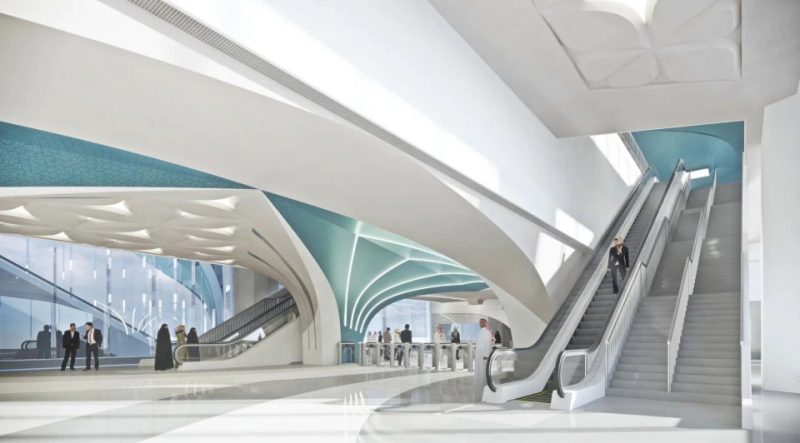

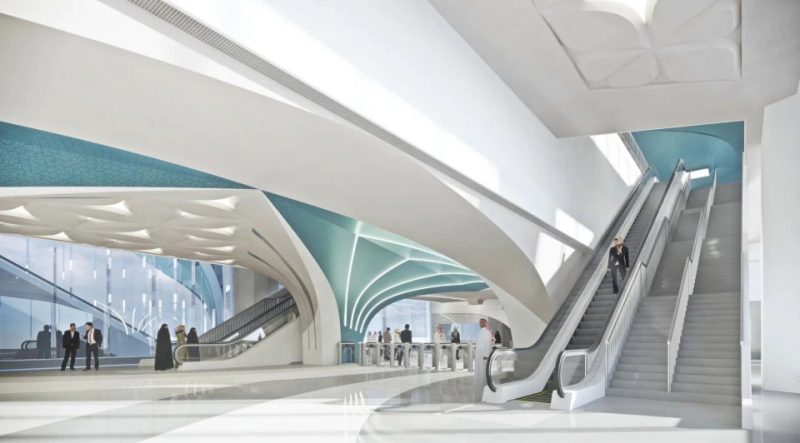

nel Group’s BIM Journey: Qatar Metro Red Line South Project

Pointing out that Anel Group had reached a significantly high level in terms of technology in the last five years, BIM Manager Ümit Balaban said, “The company’s progress in its ERP infrastructure, communication infrastructure and BIM infrastructure sets an example for digitalisation in its area of operation.”

Driven by global goals, Anel Group operates as an electrical and mechanical contracting company undertaking complex projects. Undertaking a BIM-managed metro project in Qatar in 2016, the company took action to create a structure that could support all projects under a BIM umbrella in the future. Senior management was aware of the importance of digitizing and implementing BIM processes in line with their goals.

“The approach we embraced to address this issue is a pioneering one within our area of operation,” said Ümit Balaban. “Our initial move was to create a BIM Commission that would include representatives from all departments. Thus, we were able to promote an awareness on BIM processes across the entire organization. At periodic meetings, we determined what we could improve in BIM processes and set our standards.”

“70% of the projects we take part in are managed with the BIM infrastructure and all of them are ongoing projects abroad. It was the efficiency boost and savings opportunities of Autodesk BIM Collaborate Pro and BIM 360 Docs that has enabled us to achieve this rate in the last two years.” —Ümit Balaban, BIM Manager/Mechanical Engineer, Anel Group

Ongoing progress with continuous improvements

The team responsible for the metro project in Qatar had BIM managers on board. Their feedback helped the commission further improve the processes.

Ümit Balaban said, “During the course of this project, we have developed solutions addressing several questions such as how to make cost estimates and measurements, how to transform existing legacy standards within models, how to align operation and maintenance activities with this new structure.”

In addition to the company that manages electrical and mechanical projects, Anel Doğa and Anel Marin are also Anel Group companies. Active since 2003, Anel Doğa was established as the first and only electronic waste recycling plant in Turkey. Anel Marin, on the other hand, has been providing a wide range of services to the shipbuilding industry, including concept and configuration design, equipment, project management and consultancy, manufacture of panels and control consoles, design and manufacture of special military systems, system testing and commissioning, maintenance-repair activities, since 2005. “The know-how and experience of these two companies enable us to broaden our horizon as well as improving our BIM processes,” added Ümit Balaban.

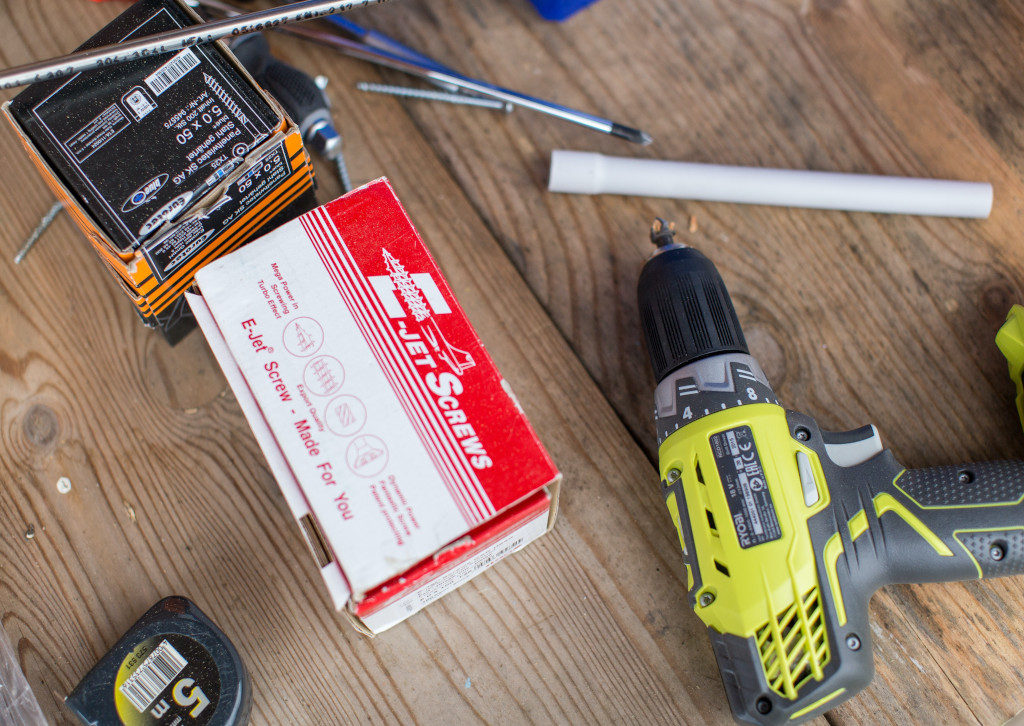

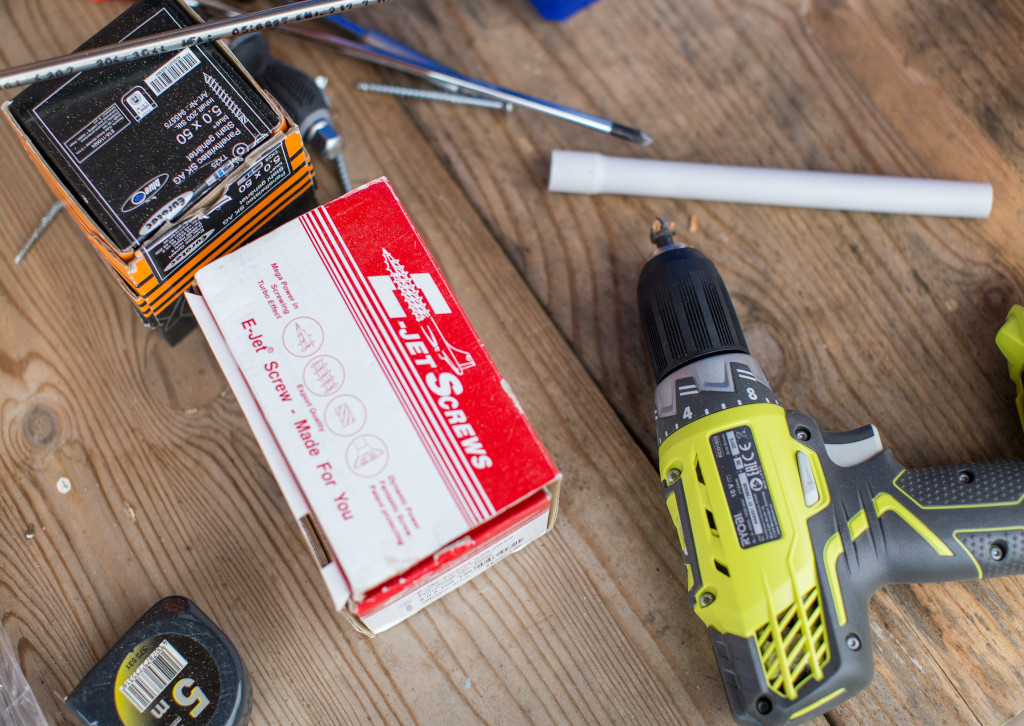

Piloting Autodesk BIM 360 Glue and BIM 360 Field for the metro project in Qatar

In addition to the numerous BIM-aligned projects that Anel Group has completed abroad, its ongoing projects include Amsterdam Schiphol Airport New Pier in the Netherlands, the University College London Hospital Proton Therapy Center in the UK, Abu Dhabi International Airport Terminal Building and Dubai – I (Bluewaters) Terminal Building in the UAE, Semaisma Road and Infrastructure Work in Qatar, Lusail Katara Hotel and Lusail Plaza Towers projects.

BIM managers supervise each project and receive support from the head office in Istanbul. Ümit Balaban stated, “During the pandemic, when we could not visit the project locations, we started to transform our head office in Istanbul into a main design office. We started using Autodesk Construction Cloud’s BIM 360 Docs solution in 2019, and it has become our primary platform following the pandemic.”

The metro project launched in Qatar was considered a pilot. First, two tablet computers were purchased. They tested ways through which they could communicate with the field via BIM 360 Field & Glue mobile apps using tablets, monitor man/hour, and devise quality control lists from a small office located at one of the emergency exits on the metro line. Balaban also added, “With a very modest investment, we accumulated valuable know-how and experience even during the pilot phase.”

Know-how and experience shift from being individual assets to being corporate value

“Our BIM approach and the use of Autodesk BIM Collaborate Pro enabled us to transform know-how and experience from being individual-centric to being corporate assets,” noted Balaban.

Now, it is possible to easily access to and align our activities with all BIM processes and standards thanks to the document management features on Autodesk BIM Collaborate Pro. Even if any BIM manager leaves a project, the successors are quickly onboarded to continue working with the same standards. The BIM platform offers a structure that allows corporate memory creation as well as know-how and experience retention.

Contribution of BIM expertise to global business opportunities

As a publicly traded company, Anel Group differentiates itself from its competitors with its transparent structure. BIM processes can help companies with transparent management to achieve significantly successful results. The fact that coding and drawing standards serving global efficiency, such as equipment order codes, have been established within Anel Group, can be cited among the outcomes of transitioning to BIM processes.

Ümit Balaban said, “This is a perpetual process that is an absolute necessity for development. If a project necessitates BIM by design and you do not have your own corporate structure to accommodate it, you can only achieve partial success and will have to deal with low efficiency. Our expertise in this field positions us well to be commissioned by major Turkish and foreign contractors that have a good command of BIM processes.

70% of the projects we take part in are managed with the BIM infrastructure and all of them are ongoing projects abroad. It was the efficiency boost and savings opportunities of Autodesk’s BIM Collaborate that has enabled us to achieve this rate in the last two years.”

utodesk’s BIM Collaborate Pro for the future

Ümit Balaban said, “Autodesk BIM Collaborate Pro, which we have used since 2019, is our main application. Firstly, we used BIM 360 Build to track the progress of the field, then utilized the quality checklists. Afterwards, we switched to BIM Collaborate Pro to rid ourselves of the labor and cost burden of installing a Revit Server on-site. This move provided us with a great advantage in design budgets.”

Balaban also added, “This approach delivered significant benefits during the University College London Hospital Proton Therapy Centerproject in the UK. We ensured that the project was delivered with an asset model created,” and noted that the deliveries of the ongoing construction projects in Qatar would also be made with asset models.

Balaban said, “Thanks to the coding standards we introduced with BIM, we integrated this model, which was often overlooked by employers, leading to a costly outcome, into our processes. Seeing the cause-and-effect relationship in these projects first hand, we have achieved a highly significant level of company-wide adoption of the BIM processes.”

Productivity boost driven by collaboration and coordination

The document management features of Autodesk BIM 360 Docs further consolidates collaboration and coordination capabilities while also ensuring efficient use of teams.

Ümit Balaban said, “We used the Autodesk BIM Collaborate Pro approach in nearly all the stages of our airport project in the Netherlands. We use the Review Process feature of Autodesk BIM 360 Docs very effectively. With the Review & Approval feature, you can track all the steps and tasks of a project on an individual basis. It ensures transparency in every step. Engineers, who used to only look at the survey of the sheets, have to look more carefully at the label within the sheets and the dimensions of the channels and really focus. User experience is really evolving. It is safe to say that this a true evolutionary process for the construction industry.”

With the integration of Autodesk BIM Collaborate Pro into the business intelligence platform PowerBI, it is also possible to turn the results into charts and present them to the top management.

Saving time, paper and labour costs

Anel Group ensured that sheet revision notes were recorded on Autodesk BIM Collaborate Pro. Draftspeople began to read those notes through Autodesk BIM Collaborate Pro and apply them. With the possibility to track the steps, which could not be monitored with the previous method, unnecessary repetitive work, unmeasurable loss of time, and the need for sheet printouts have been eliminated.

The field management features of BIM 360 Build have also delivered significant benefits. Ümit Balaban describes them with an example: “Depending on project locations, some construction projects may be halted due to weather conditions or the employer may ask us to proceed regardless of the conditions. In such cases, you or your subcontractor may need to charge a fee for extra costs. “

Since everything is recorded on BIM 360 Build, you can easily monitor whether the employer received a revised quote and whether the extra cost has actually been incurred. The result can be reached by looking at the number of workers in the field, weather conditions and other data. Being able to record the process in its entirety ensures transparency.”

This structure also allows for an accurate evaluation of the subcontractors. The company name, number of workers, total time and progress are all recorded with the document management feature of BIM 360 Field. With the integration of BIM 360 Field Management into the business intelligence platform PowerBI, it is also possible to turn the results into charts and present them to the top management. These charts also show which subcontractor would be the best to work with in the next stage.

Labour savings in the Quality Control process

Using BIM 360 Field Management also offers benefits for the quality control process. With the legacy methods, it would take 80-100 minutes to prepare an average quality checklist. BIM 360 Field Management saved us close to 50 minutes in each checklist. We owe this time saved to the fact that BIM 360 Field Management allows you to instantly add the relevant document while devising the checklist as the documents are also on the same platform. Similarly, it is possible to link the list to documents or to put dots on it and link them to the equipment.

Ümit Balaban said, “Considering that a project is completed with 2,000 to 5,000 checklists, we can achieve a significant level of man/hour savings. One of our current projects was completed with 3000 checklists, saving us a total of 800 man/hours. This is just the tip of the iceberg as it has only been a few months since we started using the checklist function of BIM 360 Field Management. Once we start using the material approval checklists, we expect to see a further increase in our savings. Especially when you have operations abroad like we do, it is possible to get the return on your initial investment within a very reasonable time and manage more projects with the same teams.”

ccelerated improvement process with Forge and Dynamo

Ümit Balaban pointed out that there were many experts both within Anel Group and among Autodesk users who coded using Dynamo and that they were always on the lookout for codes that could be useful for them.

He said, “For instance, one of our BIM managers in Qatar wrote a code on Dynamo that allowed for the scaffolding system of a 40-meter tunnel to be automatically placed according to the data received. It was a code that helped us to significantly reduce the man/hours and to streamline our work.”

Stating that they also had an application which was written on Dynamo and which they used for cost estimation and quantity surveying, Balaban said, “In line with the volumes indicated in the planning, we wrote a code for the location of the objects that corresponded to those volumes, and we determined the costs and quantities based on this code. We have also started using Autodesk’s cloud-based development platform Forge. We are using Forge to ensure that the data extracted from BIM 360 Docs is well integrated into the applications on our platform called ‘Digital Anel’ and smoothly communicates with PowerBI.”

Anel Group Tender and Purchasing Director K. Serkan Kılıç said, “We leverage our engineering power to create solutions and aim to use cutting-edge technologies that we could benefit from the most. Autodesk has always been a trusted companion. Especially in a two-year retrospect, Autodesk AEC Collection, BIM 360 Docs, BIM 360 Field and Autodesk BIM Collaborate Pro cloud solutions have helped us immensely as we seized opportunities around the globe. These technologies provided us with the agility to quickly adapt to remote working conditions, enabling us to use our teams in the most effective way possible, boost our operational efficiency and drive our costs down.”

The post A Connected BIM Approach Helping to Achieve High Levels of Productivity for the Anel Group appeared first on Digital Builder.